But once inspectors got there, they realized the problems at the Tyson plant went far beyond one injured hand. They discovered more than a dozen serious violations, including failing to provide protective equipment, a lack of safety guards on moving machines that left employees exposed to a risk of amputation, letting carbon dioxide levels surpass the permissible limit, and no training for workers about the hazards of peracetic acid, a highly hazardous chemical that’s used as a disinfectant, which can cause burns and respiratory diseases. Workers are also at risk of slipping and falling due to a lack of adequate drainage and exposed to fire hazards from improperly stored compressed gas cylinders.

OSHA announced on Tuesday that it was fining the company $263,498 for two repeated and 15 serious violations, including improper drainage, holes in the floor left without guards, a lack of guards on dangerous machinery, obstructed fire exits, and storing chemicals in a hazardous manner.

OSHA’s enforcement actions come as part of the agency’s recent focus on the poultry industry. And it also comes after a number of reports have exposed the gruesome conditions that workers must endure inside these plants.

In a report released in October, Oxfam America found that line processing speeds have increased drastically, with an official upper level of 140 birds per minute but with the possibility of going even higher if supervisors who run the lines decide to speed it up. Workers told Oxfam they process 35 to 45 birds per minute. Meanwhile, they must perform multiple motions on each bird, such as cutting, hacking, hanging, pulling, and twisting, repeatedly and forcefully 20,000 times a day.

The speed and repetitive motions combine to create a number of physical problems, such as pain in fingers, hands, arms, shoulders, and backs, as well as swelling, numbness, tingling, twitching, stiffness, and a loss of grip.

Workers also told Oxfam that they were frequently exposed to harsh chemicals, such as chlorine and ammonia, used to clean up the blood and other drippings from the birds.

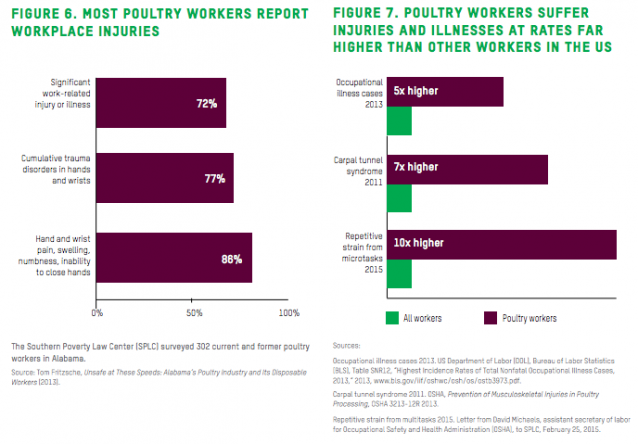

The conditions lead to widespread injuries and illnesses. Poultry plant workers experience repetitive strain at 10 times the rate of the overall workforce, carpal tunnel at seven times the overall rate, and musculoskeletal disorders at five times the rate.

“While the findings from this plant in Texas are disturbing, they’re not surprising,” said Oliver Gottfried, Oxfam’s senior campaign strategist, in a statement. “The repeated and serious violations exposed during this investigation corroborate conditions Oxfam has heard from workers at a half-dozen Tyson plants across the country.”

Oxfam’s findings were backed up in May, when the Government Accountability Office released its own report. It found that poultry and meat workers are at twice the risk of being injured on the job compared to other American workers, and they experience higher illness rates than other manufacturing employees. Many poultry workers report respiratory issues thanks to breathing in chlorine. There is also a high rate of deaths, with 151 poultry workers dying on the job between 2004 and 2013.

Workers must put up with other torturous conditions. A big problem is the lack of breaks to go to the bathroom and eat meals. Because they have to get a supervisor’s permission to leave the line and another employee to cover their spots, workers report often waiting an hour or more to get a break to relieve themselves. To cope, some say they have severely cut back on drinking liquids or even started wearing diapers.

For putting up with these hellish conditions, workers are rewarded very poorly. Average hourly pay is $11 an hour, which comes to between $20,000 and $25,000 a year, qualifying workers with children for food stamps and other government assistance programs. For every consumer dollar spent on a chicken product, a worker will see just two cents.

Tyson now has 15 days to either address the violations and pay the fines or contest them. But OSHA doesn’t have a great track record in getting the full amount it originally fines companies, as they are often able to contest and reduce them to sums that amount to a slap on the wrist. It’s rare to even get an OSHA inspection, as the agency is so under-budgeted and understaffed that a given workplace only sees a federal inspector once every 139 years.

This article was originally posted at Thinkprogress.org on August 17, 2016. Reprinted with permission.

Bryce Covert is the Economic Policy Editor for ThinkProgress. Her writing has appeared in the New York Times, The New York Daily News, New York Magazine, Slate, The New Republic, and others. She has appeared on ABC, CBS, MSNBC, and other outlets.