UNDER CAMBODIAN LAW, THE RIGHT TO ORGANIZE IS SUPPOSED TO BE IRONCLAD. No employer, government agent or citizen may impede union activity. Inside the walls of Cambodia’s largest special economic zones (SEZs), however, In These Times’ reporters saw a system designed to tightly control the workforce by keeping workers fenced in and unions out. More than a dozen workers and labor activists confirmed that, while it’s not easy to independently organize anywhere in Cambodia, the law is flagrantly violated in SEZs. The result is seething discontent.

Over the past 50 years, more than half of the world’s countries have carved out pieces of their territories to hand over to foreign investors as SEZs. The International Labor Organization (ILO) estimates that more than 66 million people—most of them young migrant women—work in the world’s more than 3,000 SEZs.

After World War II, countries from Ireland to South Korea set up these zones in bids to attract foreign capital and create jobs. In the 1980s and 1990s, states in every region of the world followed suit. Today this model is experiencing a fresh surge in popularity, with countries from Burma to Cuba racing to open new zones.

“Any country that didn’t have [an SEZ] 10 years ago either does now or seems to be planning one,” the World Bank’s Thomas Farole told The Economist in 2015. But while the success of such zones is often gauged by how much foreign money they attract, or how much economic growth they generate, the voices of the millions of workers that power these spaces are seldom heard. This is the story of SEZs from workers’ perspectives.

Typically, the carrots offered investors are special tax and tariff breaks, as well as cheap land, water and electricity. In some countries, such as Pakistan and Namibia, these enclaves also confer exemptions to national labor laws. But even when this is not the case, these zones have become hotspots for workers’ rights violations.

In Shenzhen, China, one of the world’s oldest and largest SEZs, In These Times witnessed the second chapter of the SEZ story. SEZs offer the tacit—if not explicit—promise of a steady supply of cheap, biddable labor. Once an SEZ’s workforce mobilizes and begins to make demands, companies can simply move on to a new frontier. The ILO calls SEZs “a symptom of the race to the bottom in the global economy.” In Shenzhen, factory closures and redevelopment are leaving migrant workers jobless, homeless and desperate.

THE NO-STRIKE ZONE

Early SEZs, such as those established in the Philippines in the 1960s and 1970s, were “almost like labor camps,” says Jonathan Bach, associate professor and chair of the global studies program at the New School in New York. “They were separate from the cities: You would bring in the workers, you’d house them in dormitories, you’d sort of use them up and get rid of them and then get new ones. And then if the cost of doing business got too expensive, or too problematic—if there were protests or something—then you would just pack up and move somewhere else.”

This is still the model in many SEZs today. In some countries, governments have sweetened the pot by giving investors in these zones formal exemptions from national labor laws. In Pakistan, workers are forbidden to strike or take other industrial action in these enclaves. In Togo, government labor inspectors struggle to enter the zones because of laws restricting their access. The website of the Nigeria Export Processing Zones Authority declares: “There shall be no strikes or lock-outs for a period of 10 years following the commencement of operations in the zone … and any trade dispute arising within a zone shall be resolved by the Authority.”

This is still the model in many SEZs today. In some countries, governments have sweetened the pot by giving investors in these zones formal exemptions from national labor laws. In Pakistan, workers are forbidden to strike or take other industrial action in these enclaves. In Togo, government labor inspectors struggle to enter the zones because of laws restricting their access. The website of the Nigeria Export Processing Zones Authority declares: “There shall be no strikes or lock-outs for a period of 10 years following the commencement of operations in the zone … and any trade dispute arising within a zone shall be resolved by the Authority.”

But even where there aren’t these formal exemptions, local authorities in SEZs are regularly accused of turning a blind eye to labor rights violations.

HARDER IN SEZS

On the outskirts of Phnom Penh, Cambodia’s capital, lies the Phnom Penh Special Economic Zone (PPSEZ). In a nation whose main development model is to sell itself as a reserve of cheap labor and low taxation, the PPSEZ exemplifies the new economy the government is trying to build.

The nine-mile drive from the capital is a crawl along chaotic roads that stand still for 20 minutes at a time. When you turn off the dusty street and head through the zone’s imposing front gate, you enter another world: 1.4 square miles of paved roads with factories fanning out on either side.

In These Times is the guest of the public relations firm Brains Communication, which represents PPSEZ to international investors and journalists. Brains Communication chauffeurs us in an air-conditioned Mercedes with leather seats, well-insulated from the 104-degree heat.

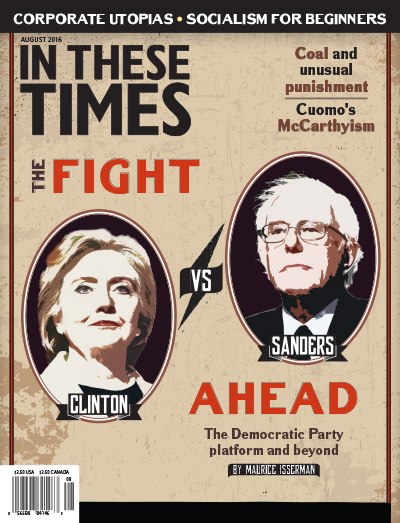

From the August 2016 Issue

This reporting was made possible by a grant from theLeonard C. Goodman Institute for Investigative Reporting. Victoria Albert contributed research.

Hiroshi Uematsu, CEO of Phnom Pen SEZ, stands outside his offices on April 4.

In keeping with the ethos of corporate control, the zone is not administered by the government but incorporated as a private company. We are going to meet Hiroshi Uematsu, the zone’s Japanese CEO.

PPSEZ’s founding mission was to attract Japanese investors to Cambodia, Uematsu says. Almost a decade later, it has succeeded in drawing 44 Japanese firms, as well as 32 companies from 13 other countries. Yamaha operates a factory there, and Coca-Cola is currently building one. Other factory names—garment manufacturer Kingmaker Footwear, diamond polisher Laurelton Diamonds—are obscure, but they are listed as suppliers or subsidiaries of some of the most famous brands in the world: Timberland, Puma, Apple, Old Navy.

Uematsu is happy in Cambodia. “I feel safe in this country,” he says. “I sometimes face [sic] directly with labor union activities … in the Philippines I have to be very careful, with smoked glass and security.”

Indeed, it’s hard to imagine a boss feeling unsafe in the pristine zone, where the chaos of the surrounding city gives way to an incongruous calm. Elsewhere in Cambodia, the landscape is very different. While we were talking to Uematsu, police clashed with about 100 protesters across town and left two activists with bad head wounds. The crowd amassed outside Cambodia’s National Assembly as it passed a new trade union law restricting independent labor organizing. The government of Hun Sen—the prime minister of Cambodia for the last 31 years, who runs a de facto one-party state under the Cambodian People’s Party—was spooked by a national strike in 2013 and moved to restrict this pole of political opposition.

Most of Cambodia’s labor force is represented by “yellow unions,” which are linked politically to the ruling party and effectively represent the government and employers, rather than workers. Cambodia’s bloc of independent unions is relatively small, but it scares Cambodia’s powerbrokers. Union leaders have been beaten, imprisoned on trumped-up charges and murdered. On January 22, 2004, Chea Vichea, the founder and leader of the Free Trade Union of Workers of the Kingdom of Cambodia and a supporter of the opposition Sam Rainsy Party, was shot in the head and chest while reading a newspaper in the street.

Garment workers gather just outside PPSEZ’s gates (L to R): Pich Sophal, 29; Sophen Leng, 29; Seng Sovirak, 26; Pheakdey Phom, 36; Sem Visal, 26.

When we return to the zone two days after our visit with its CEO, we’re traveling in a tuk-tuk with a translator from the Coalition of Cambodian Apparel Workers’ Democratic Union—an independent union group.

This time, we’ve come to meet five workers who were dismissed from the Evergreen garment factory inside the zone two years ago. The workers maintain the layoffs were retaliation. “They dismissed all the two unions’ members,” says one worker, Pich Sophal, 29, a former button-hole puncher at Evergreen.

While it is hard to organize anywhere in Cambodia, every independent union member who spoke with In These Times said it is even harder inside an SEZ.

“If the employer knows that I work for or am affiliated with the union, it means they will find any means to dismiss me,” says Sophen Leng, 29, who worked in Evergreen’s packaging department.

“After I was dismissed from Evergreen, I applied to work in another factory. The first contract is usually a short-term contract. They realized that I had union ties and dismissed me when the contract expired.”

Ou Tepphallin, deputy head of the Cambodian Food and Service Workers’ Federation, told us that SEZs also pose a challenge to independent unions simply by walling off workers.

“It’s not easy for a union leader or activist to go inside,” she says. “To coordinate [with workers], we need to make an appointment.” Even intercepting them after work is difficult, she says, because special buses wait outside the SEZ to take them to their homes.

Firing workers for organizing is illegal in Cambodia. So is hindering organizing efforts. In These Times identified eight multinationals whose products are reportedly made in Cambodian SEZs, including PPSEZ and Manhattan SEZ. Six, including Apple and Puma, have corporate codes of conduct supporting union rights.

Asked if they were aware of these apparent legal violations—and, now that they had been made aware, what they would do—only two responded by deadline. Skechers wrote that it complies with the factory operation guidelines of the Footwear Distributors and Retailers of America, which affirm the right to unionize. But it did not address any specific labor violations, and would neither confirm nor deny whether it manufactured goods in the Manhattan SEZ, as its profile on the GMAC website indicates. Levi Strauss denied that it sources products from SEZs, although a PPSEZ jeans factory lists Dockers, a Levi Strauss subsidiary, as a buyer.

UNION-FREE BY DESIGN

According to a source in civil society consulted by lawmakers in the planning stages of the 2005 SEZ Act, the Cambodian government was initially trying to carve out exemptions from labor law. The source, who spoke on condition of anonymity, tells In These Times that lawyers “were approached by the Ministry of Commerce for technical advice and one of the things was, well, how can we make the zones union-free?”

Tola Moeun, executive director of the Center for Alliance of Labor and Human Rights, also in Phnom Penh, confirms the government was planning to exempt the zones from labor law: “No freedom of association, no freedom for collective bargaining and so on. No right to strike. But after the reaction from the unions, from the development partners, from the import countries—like Europe and the U.S. and so on—then the government stepped back their plan.”

Instead, with strict control of who can enter an SEZ and impunity for organizer layoffs, it seems Cambodia simply made them de facto union-free.

81 CENTS AN HOUR

The obstacles to organizing have not stopped the rise of worker militancy in Cambodia. The main complaint is not working conditions—though some unions have demanded things like fans and clean water—but rather, low wages.

At the end of 2013, thousands of workers joined a national strike to demand a minimum wage increase from $85 to $160 a month. The government eventually increased the wage to $140 to staunch the uprising.

Sin Rlot, 39, a packaging worker, meets with organizers at a cafe just outside the walls of Manhattan SEZ on April 9.

One of the main foes of a higher minimum wage is the Garment Manufacturers Association in Cambodia (GMAC). In GMAC’s Phnom Penh offices, In These Times met with its famously irascible Secretary General Ken Loo, who believes the new minimum wage of $140 a month (which, for a 40-hour work week, works out to about 81 cents an hour) has already blunted foreign investment. The numbers indicate otherwise: According to World Bank data, foreign direct investment in Cambodia dipped slightly in 2013, then rose back to previous levels. The figures are not yet out for 2016, the year the wage hike went into effect.

“I don’t believe in a minimum wage; I believe in market forces,” says Loo. “Hardworking workers … could be earning a lot more, but … they have to subsidize the lazy bums.” He declined to say how much he is paid.

The so-called lazy bums tell a different story. “$140 a month is not enough for us, but we still do [it],” says Sokha Khan, a 36-year-old garment worker who supports her husband and children. Other workers tell In These Times that $140 a month is enough to cover one person’s living expenses, but not a family’s.

“If there was a union inside the factory, it would be good because we could demand something,” Sokha says.

It’s no accident that women are 95 percent of Cambodia’s SEZ workers. The Asian Development Bank, which promotes SEZs in the region, made explicit the logic of hiring women in a 2015 report: “It is said that females possess the nimble fingers and patience with routine tasks required by the labor-intensive processes generally occurring in the zones and that they are also less likely than males to strike or disrupt production in other ways.”

That logic does not always hold.

UNORGANIZED LABOR, WILDCAT STRIKES

A four-hour drive east from Phnom Penh and across the Mekong River, on Cambodia’s eastern border with Vietnam, sits the region of Bavet. This area was the among the most bombarded in Operation Menu, the secret 1969-1970 campaign in which the United States dropped a greater tonnage of bombs than it had on Japan during the whole of World War II.

Now Bavet’s lush fields and wide roads are home to three huge SEZs. The Manhattan SEZ opened in 2006 and has been at the epicenter of worker actions—violent and nonviolent—ever since. There are no independent unions inside its gates, and without any organized channel for worker unrest, the place is a powder keg. We get through the gates by mentioning the name of the managing director of the SEZ whom we had emailed. He’s not there, but it’s enough.

Inside, workers walk down a long thoroughfare that cuts through the SEZ, some to take their lunch break outside, others on their way home. Everyone we stop is reluctant to speak—about their work, unions or the recent militant actions.

This conversation with Daly Cayva, a 34-year-old garment worker, was a typical one:

“Where do you work?”

“A garment factory.”

“How much do you get paid a month?”

“Between $140 and $150, based on the section I work in.”

“Is that enough to live on?”

“We can say it is affordable.”

“Are you a member of a union?”

“No.”

“Why?”

“I don’t know about the union.”

“Wouldn’t a union make it better for you—you could get more money?”

“I don’t know about the union here.”

“Is it dangerous to join a union here?”

“I don’t know about that.”

“Is it dangerous for you to talk?”

“It is hot and I have to go home.”

Ath Thorn, president of the Cambodian Labor Confederation, is not surprised that no one wants to talk about unions. In February 2012, three women were shot at a protest for higher wages in the Manhattan SEZ. The incident happened in front of the Taiwanese-owned Kaoway Sports factory, whose clients include Puma. Since then, Thorn says, “They are really strict. Now they do not allow our union to organize over there.”

But making independent organizing impossible has had unintended results. “From time to time, this zone is very interesting,” says Thorn. “If they want to increase their salary, they mobilize without a leader and join together. If they want to do something now, they will strike in the whole zone. But when we are not allowed easy access inside, it’s not managed there, so violence happens during every protest.”

As worker grievances have fewer avenues of expression, and government crackdowns get harsher, many predict more explosions of frustration. Warehousing workers within walls only works for so long.

THE POSTER CHILD FOR SEZS

Although China didn’t open its first SEZ until 1980, its zones are among the most famous. Today, China contains as many as 40 million—almost two-thirds—of the world’s SEZ workers.

The Shenzhen SEZ, in southern China along the border with Hong Kong, was the country’s first. It was opened in 1980 by the leader of the Communist Party, Deng Xiaoping, as the leading edge of his sweeping economic reforms. Jonathan Bach notes that Shenzhen always had different ambitions than most SEZs: It was “more about importing particular ideas about the market and labor and capital, and using those ideas to influence the rest of the country.”

At the time, Shenzhen was a relatively small tract of land carved out of an otherwise rural area devoted to farming and fishing. Shenzhen has since expanded to cover almost 800 square miles. The megacity’s total economic output is equivalent to or greater than that of Ireland or Vietnam. Its tens of thousands of factories have produced millions of iPhones, handbags, jeans and more for export around the world.

Ath Thorn, president of the Cambodian Labor Confederation, at the offices of the Coalition of Cambodian Apparel Workers’ Democratic Union on April 5.

In 2010, Shenzhen celebrated its 30th birthday with fanfare and fireworks. China’s President Hu Jintao traveled to the city and hailed it as “a miracle.” Many of the policies pioneered there, like short-term labor contracts and performance-based wages, have since been rolled out nationwide. The SEZ model has been credited with driving China’s industrialization and explosive, manufacturing-based economic growth.

To entice foreign investors into Shenzhen, the central government gave the zone the power to set its own tax and other business incentives. But Shenzhen had something else to offer foreign firms looking for cheap places to make their products: a labor force of millions of migrants from rural China.

China’s hukou system of household registration, introduced in the late 1950s to curb urbanization, severely curtails these migrants’ rights. Hukou ties access to services, such as subsidized healthcare and education, to place of permanent residency. Migrant workers can rarely get that place altered.

To supply factories with a constant stream of labor, migrant workers were issued temporary resident permits—but only if they had a job. With their legal residency tied to their employer, losing their job meant exile—or a risky, undocumented existence. Anita Chan, a researcher at Australian National University, likens Shenzhen under the hukou system of the 1990s to apartheid in South Africa under the pass system.

Some factory bosses devised strategies to tighten the screws, requiring workers to pay “security deposits,” or seizing their identity documents. Many workers lived in housing tied directly to employment, in what Pun Ngai, a professor at Hong Kong Polytechnic University, has called a “dormitory labor regime.”

In the 1990s and early 2000s, Shenzhen became almost synonymous with sweatshop globalization, with reports of workers toiling incredibly long hours in unsafe factories to make things like Mickey Mouse books, Teletubbies and Reeboks. Wages were not necessarily lower inside the SEZ, but conditions were often dire. Mandatory and unpaid overtime were commonplace.

Workplace injuries have also scarred many of the migrants who powered Shenzhen’s boom. Huang Ming (a pseudonym), a 60-year-old migrant worker from western Guangzhou who came to Shenzhen in 1997, says that two years after his arrival, he was injured at work. “I was soldering tables and chairs and a spark went into my eye,” he says. “I have an official certificate, but … the company said, ‘If you want compensation, you have to resign.’”

Shenzhen is in a construction boom as factories close and financial towers rise.

The hukou system made it hard for workers in Shenzhen’s factories to fight back and secure better conditions, Chan says. But she doubts this was ever explicitly advertised to investors as a bonus for setting up shop. “They knew, they didn’t have to advertise. It doesn’t sound good. They were supposed to be socialists, you know.”

Since the 1990s, working conditions have improved across China, albeit slowly and unevenly. Hukou was “relaxed” in 2004 after the death in custody of a university graduate in the northern Chinese city of Handan who had been arrested for not having the proper papers. But the reforms only went so far, notes Chan. The arrests stopped, but “it doesn’t mean [migrants] can enjoy the same rights as the local residents.”

Wages increased, however, in part because the “one child” policy slowed population growth and reduced the surplus labor that powered the country’s manufacturing boom. Workers also became better organized and better educated about their rights, thanks largely to the tireless efforts of independent labor activists.

But migrant workers in Shenzhen face new challenges as the city pursues an aggressive agenda of “upgrading” into tech and finance. As wages increase, so does the cost of living in this increasingly flashy metropolis. Industrial areas are being transformed into office blocks. Whole neighborhoods where migrant workers have lived for decades are being demolished.

Clothing, toy and shoe factories, in particular, are moving from China to countries with lower wages, such as Vietnam and Bangladesh. Others are simply moving to provinces in inland China with lower minimum wages. In Shenzhen, reports of factories closing and bosses defaulting on paychecks have become commonplace.

The problem for Shenzhen now, says Bach, is no longer, “How do you get as many workers into Shenzhen as you can?” but rather, “How do you get the low-skilled workers demanding higher wages out?”

“Instead of the workers who used to do that lower-level work simply being retrained, you have companies just moving to wherever they can find that low-level work,” he says. “That’s the whole name of the game in the global economy: to play countries off one another. And the idea of the special economic zone was sort of to allow countries to have different jurisdictions, even within their own national jurisdictions.”

Chan gives the example of the iPhone manufacturer Foxconn—whose mercilous assembly lines infamously drove 14 workers to suicide—as a company “moving all over China, trying to get a better deal.” The practice is parallel to the way U.S. states have enticed factories with development deals and anti-union laws.

But wherever manufacturers move, they cannot expect workers to stay cheap and compliant forever.

CAPITAL’S PANOPTICON

In the 2000s, Shenzhen became a testing ground once more—this time, for surveillance technologies. The city installed 200,000 closed-circuit TV cameras in public spaces as a practice run for China’s Golden Shield program, a vast database that correlates video feeds with biometric data from cell phones and mandatory national ID cards.

Along the streets of Shenzhen today are too many surveillance cameras to count, rotating like roving eyes. Overhead, the skyscrapers shine at night in flashing, neon colors, bedecked with logos such as KFC, McDonald’s and 7-11. The effect is that of an eerie corporate utopia in which capital is wild and free, but people are heavily controlled.

Officially, the cameras are aimed at fighting crime. But Naomi Klein reported in Rolling Stone in 2008 that a Shenzhen-based company had already developed software to let “cameras alert police when an unusual number of people begin to gather at any given location.” Clearly, these measures could also be used to tighten control at a time of growing unrest.

In 2014, the China Labour Bulletin, an NGO based in Hong Kong, recorded more than 1,300 labor disputes across China. In 2015, that number rose to over 2,700—including more than one a day in Shenzhen and neighboring areas in Guangdong province. Many were prompted by factory closures, with workers accusing bosses of cheating them of full severance and social insurance payments.

In July 2015, more than 100 workers at a Shenzhen factory supplying the giant fast-fashion brand Uniqlo traveled to Guangzhou, the capital of Guangdong province, to petition Communist Party authorities. They said the factory had suddenly announced its closure and was leaving without paying its debts to workers. Shenzhen police were sent to retrieve the petitioning workers and bring them back to the SEZ, violently dragging them onto buses and detaining them for hours.

On May Day, In These Times met with workers who make eyeglasses for export to Europe and the U.S. at an enormous factory in Shenzhen’s Longgang district. First opened in the late 1980s, it is now closing as the area is “redeveloped” into offices and upscale apartments.

Huang Ming, the 60-year-old migrant worker from western Guangzhou, spoke with In These Times in the small one-room apartment he shares with his son, who also works at the factory. “Everybody in this building works there,” Huang says, sitting barefoot on the edge of the bed that takes up most of the space. Now that the factory is closing, Huang says he and many of his coworkers are forced into retirement.

If Shenzhen 1.0 was large-scale sweatshop industrialization, this is Shenzhen 2.0: a finance center where capital is king and migrant workers, having outlived their utility, are pushed out.

Later, we walk with Huang’s son Zai through the streets of Longgang. “It’s hard to get another job,” he says. “In this area they are not opening new manufacturing plants. Factories are being replaced by offices.”

Like everywhere else in the city, surveillance cameras are prominently in view in every direction—on the street, outside the factory, at the intersection, by the bus stop. We’re quite sure we’ve been on camera every step of the way.

“I’m not afraid of the government. I’m fighting for my rights,” Zai says firmly. But he adds that he’s still planning to leave Shenzhen and return to his home in western Guangzhou, because life as a migrant worker in the city, without a job, is impossible. “Many people are leaving.”

This reporting was made possible by a grant from the Leonard C. Goodman Institute for Investigative Reporting. Victoria Albert contributed research. Matt Kennard wrote this article along side Claire Provst.

This post originally appeared on inthesetimes.com on July 25, 2016. Reprinted with Permission.

MATT KENNARD AND CLAIRE PROVOST are fellows at the Centre for Investigative Journalism in London.